Sustainable Supply Chain Management Through Product Preservation and Awareness Program

© 2022 KIIE

Abstract

The effort for carbon emission reduction can be a useful measure of sustainable supply chain management and preservation technology plays an important role in reducing the rate of deterioration. In addition, the industry initiated a customer awareness program, and advertising measures are considered to control the rate of deterioration of products. A mathematical model is proposed to maximize profit by maintaining sustainability. The model is solved with a nonlinear optimization technique using closed-form solutions of the decision variables. Moreover, the model is examined with numerical experiments. Several special cases are discussed to show the maximum profit generated by the proposed model. The numerical experiments show that effort for carbon emission reduction is largely beneficial for supply chain management sustainability. It is also shown that improved preservation strategies can efficiently reduce the deterioration rates of products.

Keywords:

Sustainability, Supply Chain Management, Controllable Deterioration, Awareness Program1. Introduction

To maintain a sustainable supply chain, the supply chain must follow all three aspects of sustainability including economic, environmental, and social pillars. Industries have beenhappy to continue with economic growth among those pillars. However, the environmental pillar becomes popular nowadays based on global warming (Hammar et al., 2022). The main concern about global warming is the increasing rate of CO2 emissions. Thus, the main effort is to reduce CO2 from industries such that it will not be harmful to society. The reduction of CO2 from production can be controlled. Retailers can also use the effort to reduce CO2 by transportation policy. This research considers the effort of carbon emission reduction for both the manufacturer and the retailer.

This research fulfills this research gap that the industry can choose any of them. The effort for the reduction of CO2 is considered a decision variable because it is totally dependent on the R&D sector of any industry. In this direction, this study considers the effort of CO2 reduction with customer awareness. Because until the customer cannot have the effectiveness of CO2 reduction and others, sustainability cannot be achieved. But the customer can be attracted by several policies. If the price of the product is reduced or the quality is improved with the same price, the product sales definitely can be increased when the awareness program or awareness strategy can be introduced. Therefore, the major research gap covering the selling price dependent demand with CO2 emission reduction strategy under customer awareness is conducted within this research.

The product is considered with the direct effect of deterioration, where a preservation technology is used to reduce the rate of deterioration. The manufacturing industry has been known to offer quantity discounts to retailers for selling more product (Sarkar, 2016). Sometimes, retailers pass on similar discounts to customers, but in many cases, the retailers do not. Instead, retailers allow partial discounts to their customers (Sarkar et al., 2020). Literature in this field includes several studies on partial trade credit. Therefore, this research is conducted based on deteriorative products with preservation technology, reduced selling price to attract more customers, controlled CO2 emissions to save the environment, and customer awareness.

The rest of this paper is structured as follows: Section 2 presents a literature review. The problem definition, notation, and assumptions of the optimization model are discussed in Section 3. Section 4 presents the mathematical model and solution methodology. In Section 5, numerical experiments, a sensitivity analysis, and managerial insights are explained. Finally, in Section 6, the findings from this study are examined.

2. Literature Review

2.1 Carbon Emissions and Awareness Program

Nowadays, owing to environmental impacts, sustainable supply chain management (SSCM) is essential for businesses to remain operational for a long time. Panda et al. (2015) introduced a centralized SCM to gain more profit under several ways of channel coordination. However, they did not create an awareness program. Customers should be aware of sustainablity issues. Thus, the industry has the responsibility to take care of customer awareness programs whether in the retail industry or manufacturing industry. Both should promote awareness programs via advertising. If the advertisement is allowing more, then the demand pattern may vary as well as increase. While Sarkar (2012) used this strategy only for the retail industry, the proposed model utilized the same strategy for the supply chain. Sarkar (2012) used this for advertising only, whereas the current study utilizes this as an awareness program for the customer to help protect the environment from the effects of global warming.

Modak et al .(2016) explained about effects of duopoly retailers under a coordination policy within the supply chain players, as suggested by Panda (2014), by utilizing a revenue sharing policy. Modak et al. (2016) developed several pricing strategies without a price discount policy for duopoly retailers but only for corporate socially responsible manufacturers, whereas the proposed model considers that both the retailer and the manufacturer are socially responsible and have awareness programs for the customer. Tayyab et al. (2020) developed a process improvement under the environmental effect, but no awareness program was created. Sarkar et al. (2020) introduced an awareness program to control global warming under several conditions, but they did not consider the reduction of carbon emissions. Chen et al. (2020) discussed on the corporate strategy of ownership and location. They also took care of the environmental issues along with the business strategies. Cai and Choi (2021) gave importance on the producer’s responsibility to make a business sustainable. The proposed study develops a mathematical model under the concept of a quantity discount, and a preservation strategy to improve the quality of deteriorating products. This is the first study that considers all of these factors toward sustainable supply chain management.

2.2 Product Deterioration and Preservation Strategy

Tiwari et al. (2019) developed an ordering policy to make a system sustainable. They introduced noninstantaneous deterioration without any stochastic rate. Tiwari et al. (2019) proved that a multi-stage trade-credit strategy under controlled carbon emissions could reduce global warming. Taleizadeh and Moshtagh (2019) proved that the consignment inventory for any SCM can enable SSCM when considering quality-dependent return products. Alizadeh-Basban and Taleizadeh (2020) developed an SSCM for specific products by considering the sales effort and issues with delivery. The aforementioned studies considered the quality of products with regard to deterioration or other issues. Sarkar (2012) was the first to consider time-varying deterioration. Sarkar (2013) also introduced several stochastic deterioration rates under SCM. The major issues of stochastic deterioration were solved, but there was no known way to control the deterioration or to consider sustainability in the solution. Dye (2013) introduced the concept of cost of preservation technology, which has been the main preservation policy in studies to this date. With the assumption that deterioration might not be constant, owing to the simplicity of the model, a constant rate of deterioration was considered. Therefore, there was an immediate research gap with regard to variable deterioration and preservation technology.

Sarkar (2016) discussed several discounts polices, three-step inspections, and a variable backorder rate to control deterioration in supply chain coordination but without a preservative to increase the lifetime of products. Sarkar and Saren (2017) verified several inventory models with variable deterioration of the products without controlling their deterioration rates. Sana et al. (2018) developed a dynamic model with a supply chain cash flow without controlling the quality of products even though dynamic movement was present. Modak et al. (2018) analyzed the structural issues of a closed-loop supply chain for the quality of products with several pricing policies, but they did not consider any investment to update the quality of the products.

Sana et al. (2019) developed an improved algorithm for a production model with constraints for specific products, but there was no improvement in the quality of the products. Ullah and Sarkar (2020) updated the quality of products through a smart process using radio frequency identification. They utilized remanufacturing for low-quality products to transfer them into perfect-quality products without changing the environment of the products. However, it was possible to improve the environmental conditions for updating the quality of products. In the same direction, Saxena et al. (2020) introduced an alternative marketing strategy without changing the quality of products from deterioration. They recommended remanufacturing of the deteriorated products to make new products that might be utilized for animals rather than human beings. In this way, Saxena et al. (2020) proved that the waste can be controlled, but the initial product can be changed to any other product. Li et al. (2018) explained about forecasted demand of deteriorated products but they did not think about the reduction of deterioration. They presents the importance of using preservation technology to reduce deterioration rate of products. This study fulfills the research gap (see <Table 1>) to control the deterioration rate by an initial investment in a preservation strategy.

3. Problem Definition

Adopting effort of carbon emission reduction and awareness measures to solve the sustainability issue is the goal of this model. <Table 2> shows the notations for the mathemaical formulation.

Along with the profit of the supply chain, the players should consider the implications to society as a whole. To ensure customer awareness when conserving the environment, an advertisement strategy is adopted by the company. The manufacturer offers quantity discounts to the retailer in exchange for a large amount of purchasing to save on the holding costs of the manufacturer. In this study, some investments are assumed to increase the awareness of the customers. Therefore, the best suited demand pattern is considered to be ω=a-bp+β1(η1+η2)+β2(θ1+θ2), where a and b are the scaling parameters. The industry obtains that the demand can be increased by reducing the selling price of the product along with carbon emissions reduction, and customer awareness cost.

To increase customer demand, the stakeholders in the supply chain follow a business strategy in which the manufacturer offers quantity discounts to the retailer, and the retailer offers a percentage of this discount to the customer. The discount rate can be represented as TC(q)=ρiq, where q∈[ξi, ξi+1) and ρi is the discount cost. This can be written as

| (1) |

where ρ1 > ρ1 >⋯ > ρn.

Two types of transportation costs (fixed and variable) are utilized to transport the products from the manufacturer to the retailer. Finally, the profit is maximized by extending sustainability.

4. Mathematical Model

4.1 Model for Retailer

When the manufacturer offers large quantity discounts to the retailer, the retailer offers a partial quantity discount to customers. Thus, the cost for offering quantity discounts to the customer is x1 TC(q). To reduce global warming and pollution, the retailer invests as the effort to reduce carbon emissions. The retailer also takes part in a similar awareness program for customers. Thus, there is an investment from the retailer for the same purpose. Hence, the customer awareness cost is . As the fixed and variable logistics costs are considered to transport products, the total logistics costs are given by zFR+VRzq. When dealing with highly deteriorated products, the retailer has to pay the deterioration cost and the corresponding preservation cost. The manufacturer sends products following the single setup multi-delivery (SSMD) policy. Thus, the ordered lot size Ω=zq. Owing to deterioration and using preservation technology, the value of q can be written as , where ωτ3 represents the market demand, and is the deteriorated item during τ3. As , q can be written as

| (2) |

Hence, the retailer’s average inventory can be written as

| (3) |

The total of deteriorating items of the retailer is the difference between the total products received from the manufacturer and the fulfillment of customer demand. Therefore, the number of deteriorating items of the retailer can be written as

| (4) |

Hence, from Equations (3) and (4), it can be written as . Then, the retailer’s ordering cost is for purchasing from the manufacturer, and the holding cost for retaining perfect products is . The deterioration cost after using preservation technology is . Finally, the revenue

of the retailer is pω, where the purchasing cost is μω. Therefore, the total profit per cycle for the retailer is given by

| (5) |

4.2 Model for Manufacturer

The manufacturer produces products and sells them to the retailer. The rate of deterioration is high, and both the manufacturer and retailer have to deal with this problem. The manufacturer utilizes a preservation policy to control the deterioration rates of products. The manufacturer assumes responsibility of social activity to control the carbon emissions, and conducts an awareness program for the customers. To determine the manufacturer’s profit, the following costs and revenue calculations-should be considered.

The manufacturer’s total inventory can be calculated as follows: The production lot size of the manufacturer is Ω=zq+ϕ, where ϕ is the number of deteriorated items. This can be expressed as ϕ=χ1ΓM. The total number of deteriorated items of the supply chain is . Therefore, it can be written as

| (6) |

After simplification, the inventory of the manufacturer can be written as (Sarkar, 2013)

| (7) |

To produce products, the manufacturer has to establish a production system. The corresponding cost is the known setup cost, which is given by . There is a significant amount of deterioration in products. Thus, calculation of the average inventory for the perfect product is needed to calculate the holding and deterioration costs. The holding cost can be found as , and the deterioration cost is . To control the deterioration rate, a preservation policy is adopted by the manufacturer. The manufacturer uses κ1 investment for the preservation technology to reduce the deterioration. Therefore, the cost of deterioration after using preservation technology is , where V1(κ1) is the reduction rate of deterioration. The manufacturer utilizes the customer awareness investment , and the effort for reduction of carbon emissions investment is . To sell more products, the manufacturer offers quantity discounts to the retailer. Thus, the quantity discount cost is . Finally, the revenue of the manufacturer is given by μω, and the purchasing cost of the raw material is γω. Therefore, the profit per cycle for the manufacturer is given by

| (8) |

Finally, the total profit of the entire supply chain is given by

| (9) |

4.3 Solution Methodology

In the proposed model, the deterioration rate is considered to be random and follows a uniform distribution. Thus, the deterioration rate can be written as . After simplifying, Equation (9) becomes

| (10) |

The model is optimized by a classical optimization method. The optimum values of the decision variables can be obtained as follows:

- - The number of shipments is considered an integer variable.

- - Taking the partial differentiation of Equation (10) with respect to q and satisfying the necessary condition of optimization, one can obtain the optimum value of q as

| (11) |

From Equation (11), it can be concluded that the optimum delivery lot size is directly proportional to the demand of the customer, ordering cost of retailer, setup cost for manufacturer, fixed transportation cost of the retailer. The lot size is inversely proportional to the deterioration rate and cost of products.

To find the optimum value of κ1, Equation (10) is partially differentiated with respect to κ1. Using the necessary condition of optimization, one can obtain

| (12) |

The optimum investment for preservation technology depends on the ordering cost for retailer, setup cost of manufacturer, fixed and variable transportation cost, production cost, and preservation cost for both players. For the optimum value of θ1 and θ2, taking and , one can obtain

| (13) |

| (14) |

The optimum carbon emission cost for manufacturer and retailer are represented by Equation (13) and (14). Both the optimum values are directly proportional to the selling price of manufacturer and retailer, ordering cost of retailer, holding cost of manufacturer, setup cost of manufacturer, and the transportation cost of retailer. The optimum costs are also dependent on investment for preservation technology. The optimum values of η1 and η2 can be obtained by equating and . Therefore,

| (15) |

| (16) |

Equation (15) and (16) represent the optimized values of customer awareness costs of manufacturer and retailer. These optimum values depends on the selling price of manufacturer and retailer, ordering cost of retailer, holding cost of manufacturer, setup cost of manufacturer, and the transportation cost of retailer. The optimum value of p can be calculated by equating , and the optimum value is

| (17) |

The optimum selling price is represented by Equation (17). The optimum value is dependent on demand and ordering and transportation cost of retailer, setup, holding, and deterioration cost of manufacturer, and preservation technology. (See Appendix I for detailed calculations of the optimization and values of J1, J2, J3, J4, and J5).

Now, by the Hessian matrix, it can be proven that the values of the decision variables are a global optimum. Since z is the integer variable, the Hessian matrix of the other decision variables can be written as

| (18) |

The first principal minor of the Hessian matrix is given by

| (19) |

The second principal minor can be written as

| (20) |

The third principal minor is given by

| (21) |

The fourth principal minor is given by

| (22) |

The fifth principal minor can be written as

| (23) |

Similarly, the sixth principal minor H66 > 0 and the seventh principal minor H77 < 0 are obtained.

Thus, from the sufficient condition of optimization, it can be found that all principal minors alternate in sign. Therefore, it can be said that all decision variables along with the profit of the SSCM are a global maximum.

5. Numerical Experiments

The numerical experiments were performed in Mathematica 11.3. In this section, numerical examples with three special cases, a sensitivity analysis, and managerial insights are presented.

5.1 Numerical Examples

The numerical data are taken from Sarkar (2013) and Modak et al. (2016). To validate the model, several experiments are conducted. The input data are given as follows: γ=$2/unit, a=1,600, b=18, β1 = 8, β2 = 9, AR =$25/order, HR =$70/unit/year, HM =$60/unit/year, CM =$350/setup, CDR =$150/unit, CDM =$400/unit, P=2,000 units, U1 =0.01, U2 =0.2, y1 =0.1, FR =$50/shipment, V=$30/unit/shipment, x1 =70%, ρ=$0.025, α1 =50, α2 =15, α3 =2, and α3 =60.

At the optimum number of shipments z=3, the optimum delivered lot size is 1,389.98 units/shipment. The retailer invests optimal costs for customer awareness and efforts for reduction of carbon emissions are $136.75/cycle and $46.15/cycle, whereas for the manufacturer, the investments for the same purposes are $1,025.60/cycle and $38.46/cycle, respectively. The optimal investment for the preservation technology is $529.05/cycle. The retailer sells products to the customer at optimum price $391.39/unit. Thus, the maximum supply chain profit is obtained as $366,734/year.

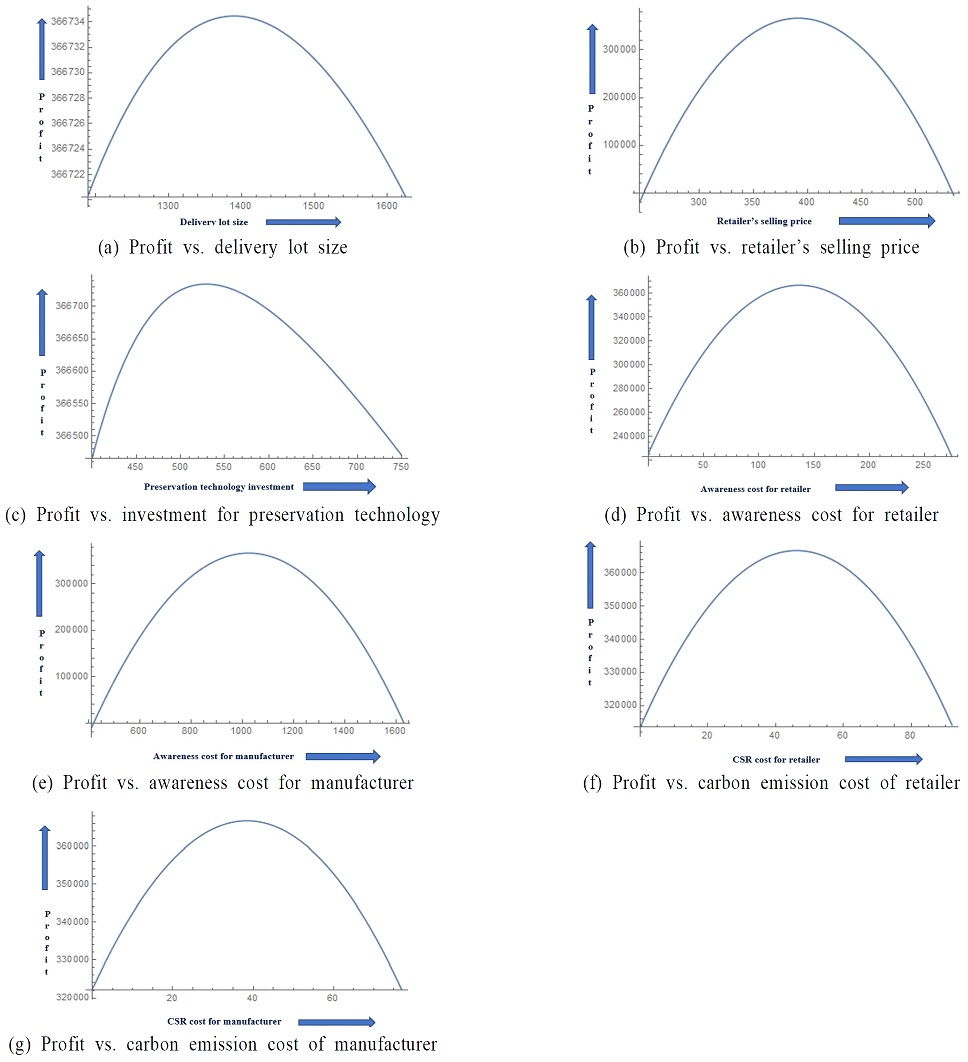

The change in the profit using SSCM with changes in the values of the decision variables can be explained as follows: From <Figure 1a>, it is seen that the profit of the SSCM becomes zero when the delivery lot size is about 1190 units/shipment and 1,625 units. The optimum profit can thus be obtained when the lot size is about 1,390. Thus, it can be concluded that the optimal value of the delivery lot size is 1,389.98 units/shipment.

The selling price of the product varies between $250 and $535. <Figure 1b> shows that when the selling price becomes about $250, the supply chain starts to gain profit, and it turns maximum when the selling price is $391.05. If the selling price becomes $535, then the supply chain runs at a loss. As the rate of deterioration of green products is high, investments in preservation technology are essential. These investments vary from $400 to $750 (see <Figure 1c>) when the supply chain gains profit, and the optimal value of the investment is $529.05.

<Figure 1d> and <Figure 1e> represent the changes in profit with respect to the awareness cost of the retailer and the manufacturer, respectively. The optimal awareness cost for which the profit is maximum is about $1,37, whereas for the manufacturer it is about $1,025. Thus, the manufacturer needs to invest more than the retailer to gain maximum supply chain profits for awareness of the customer. The optimal investment for the effort of carbon emissions reduction of the retailer is (see <Figure 1f>) near $46, where the total supply chain profit is maximum. To gain the maximum profit for the supply chain, the manufacturer needs to invest $39 (see <Figure 1g>), which is almost less than the retailer’s investment.

5.2 Special Cases

For the purpose of comparison, three special cases are considered as follows: Case 1) when demand is considered as a constant, Case 2) when preservation policy is not considered and Case 3) when effort for carbon emission reduction is not considered

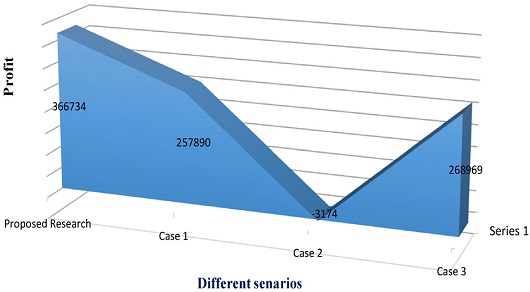

If the demand is considered as a constant, then the total profit of $257890/year is less than the total profit of the proposed model. This indicates that the selling price significantly effects the total profit of the supply chain. In general, the demand for a green product is not constant. Therefore, this proposed variable converges over a constant demand pattern.

If no preservation policy is considered, then the profit of SSCM becomes TPSCM =$-3,174.51/cycle, which is negative. This means if the preservation technology is not considered, then the SSCM will face a loss. However, it is quite natural that if green products are significantly deteriorated and no preservation effort is taken, then there is a large amount of deteriorated products. As a result, the profit definitely decreases. Therefore, the proposed model converges over the nonpreservation models.

If the industry is not taking any initiatives to control pollution or global warming, then from the government’s perspective, it is very difficult to maintain the carbon emissions from industry. Therefore, if there is no effort of carbon emission reduction, then the profit of the SSCM is TPSCM =$268,969/cycle, which is less than that of the proposed model. Thus, if the players of SCM consider carbon emission reduction, then they can obtain a greater profit and can take care of the environment.

Now, if these three special cases are compared with the proposed model, from <Figure 2>, it can be shown that the profit of the supply chainis maximum for the proposed method. If demand is considered constant, then the profit is lower. The supply chain may face loss if preservation technology is not considered. For carbon emission reduction strategy, the profit is less than that of the current study when it is not considered.

5.3 Sensitivity Analysis

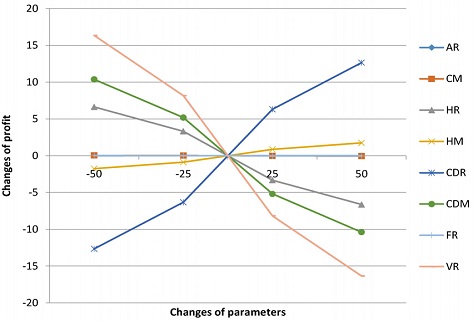

The changes in the profit respect to some key parameters are listed in <Table 3> and shown in <Figure 3>. From a graphical representation of the sensitivity of the key parameters of this study, the following insights can be drawn.

First, the ordering cost of SSCM is maintained in the equilibrium position if one can increase toward the positive or negative direction. For the SSMD policy, this cost is very important for placing orders repeatedly as weakly or based on anytime scheduled or random order. This indicates that the ordering cost is totally steady over the cycle time. Therefore, management can try a random order to check the validity of the cost during random ordering and can check the status of carbon emission reduction.

Second, SSMD policy is always important for the holding costs of the retailer and manufacturer. When the holding cost increases, the total cost of the manufacturer increases. However, owing to the SSMD policy, the reverse occurs. The profit of the manufacturer increases with an increase in the holding cost of the manufacturer. However, for a retailer experiencing an increase in the holding cost, the profit of the SSCM decreases. If the study follows a single-setup-single-delivery policy, then for both cases, the profit decreases with an increasing rate of holding cost. However, for both players, the holding cost follows an equilibrium position.

Third, the setup cost is much less sensitive here because a traditional production system is used. However, this still maintains an equilibrium in changes and other parameters.

Forth, the variable transportation cost is very sensitive in this study. The profit decreases significantly with an increase in this cost, although it maintains equilibrium in both directions. This is the most sensitive parameter among all of the parameters. Meanwhile, the fixed transportation cost is much less sensitive than the variable transportation cost. As the quantity is involved with the variable transportation cost, which is a decision variable for transporting products through SSMD policy.

Lastly, since the duration of the preservation of products is a major contribution in this model, the deterioration cost for both the retailer and manufacturer fluctuates in the reverse direction. For the manufacturer, the profit decreases when the deterioration cost increases; but for the retailer, the profit increases when the deterioration cost increases. This occurs owing to the use of preservation technology. The number of deteriorated products decreases when preservation technology is used, and the profit increases.

6. Conclusions

A mathematical model was developed for supply chain management to maintain sustainability. It was recommended that the use of green products can reduce the carbon emissions from different production systems. However, it was found that the deterioration rate of green products was much faster than for other products. Therefore, more preservation technological investment should beutilized. Also, to increase customer awareness, a significant amount of investment should be utilized for advertisements. Finally, the total cost can be minimized under the effort of carbon emissions reduction. This proved that if customer awareness can be increased, then environmental pollution can be controlled such that sustainability could be established easily. Several numerical experiments and special cases were discussed with some major managerial insights. It was found from a sensitivity analysis that the awareness cost parameter and effort of carbon emission reduction had a greater impact than other parameters. This model proved that industry can take a major role in controlling the global warming issue by introducing a customer awareness strategy. However, in this paper, constant demand pattern was considered and it can be extended as stochastic for further extension of the model. For quantity discounts, a trade-credit policy can be accommodated to increase revenue, and this is another fruitful direction for research. If the unequal power of the supply chain is considered, then a leader-follower strategy can be developed to verify the CSR again with new findings.

Acknowledgments

This work was supported by the National Research Foundation of Korea(NRF) grant funded by the Korea government (MSIT) (NRF-2020R1A2C1005489).

References

-

Alizadeh-Basban, N., and Taleizadeh, A. A. (2020), A Hybrid Circular Economy-Game Theoretical Approach in a Dual-Channel Green Supply Chain Considering Sale’s Effort, Delivery Time, and Hybrid Remanufacturing, Journal of Cleaner Production, 250, 119521.

[https://doi.org/10.1016/j.jclepro.2019.119521]

-

Cai, Y. J., and Choi, T. M. (2019), Extended Producer Responsibility: A Systematic Review and Innovative Proposals for Improving Sustainability, IEEE Transactions on Engineering Management, 68(1), 272-288.

[https://doi.org/10.1109/TEM.2019.2914341]

-

Chen, H., Zeng, S., Yu, B., and Xue, H. (2019), Complementarity in Open Innovation and Corporate Strategy: The Moderating Effect of Ownership and Location Strategies, IEEE Transactions on Engineering Management, 67(3), 754-768.

[https://doi.org/10.1109/TEM.2018.2889804]

-

Dye, C. Y. (2013), The Effect of Preservation Technology Investment on a Non-instantaneous Deteriorating Inventory Model, Omega, 41(5), 872-880.

[https://doi.org/10.1016/j.omega.2012.11.002]

-

Hammar, T., Hansson, P. A., and Röös, E. (2022), Time-dependent Climate Impact of Beef Production – Can Carbon Sequestration in Soil Offset Enteric Methane Emissions? Journal of Cleaner Production, 331, 129948.

[https://doi.org/10.1016/j.jclepro.2021.129948]

-

Li, L., Liu, M., Shen, W., and Cheng, G. (2018), Product Deterioration Based Demand Forecasting and Service Supply Model for MRO Service Chain, IEEE Transactions on Engineering Management, 67(1), 187-200.

[https://doi.org/10.1109/TEM.2018.2867842]

-

Modak, N. M., Panda, S., and Sana, S. S. (2016), Pricing Policy and Coordination for a Two-layer Supply Chain of Duopolistic Retailers and Socially Responsible Manufacturer, International Journal of Logistics Research and Applications,19(6), 487-508.

[https://doi.org/10.1080/13675567.2015.1085499]

-

Modak, N. M., Panda, S., and Sana, S. S. (2016), Three-echelon Supply Chain Coordination Considering Duopolistic Retailers with Perfect Quality Products, International Journal of Production Economics, 182, 564-578.

[https://doi.org/10.1016/j.ijpe.2015.05.021]

-

Modak, N. M., Modak, N., Panda, S., and Sana, S. S. (2018), Analyzing Structure of Two-echelon Closed-loop Supply Chain for Pricing, Quality and Recycling Management, Journal of Cleaner Production, 171, 512-528.

[https://doi.org/10.1016/j.jclepro.2017.10.033]

-

Panda, S. (2014), Coordination of a Socially Responsible Supply Chain Using Revenue Sharing Contract, Transportation Research Part E: Logistics and Transportation Review, 67, 92-104.

[https://doi.org/10.1016/j.tre.2014.04.002]

-

Panda, S., Modak, N. M., Basu, M., and Goyal, S. K. (2015), Channel Coordination and Profit Distribution in a Social Responsible Three-layer Supply Chain, International Journal of Production Economics, 168, 224-233.

[https://doi.org/10.1016/j.ijpe.2015.07.001]

-

Sana, S. S., Ferro-Correa, J., Quintero, A., and Amaya, R. (2018), A System Dynamics Model of Financial Flow in Supply Chains: A Case Study, RAIRO-Operations Research, 52(1), 187-204.

[https://doi.org/10.1051/ro/2017025]

-

Sana, S. S., Ospina-Mateus, H., Arrieta, F. G., and Chedid, J. A. (2019), Application of Genetic Algorithm to job Scheduling Under Ergonomic Constraints in Manufacturing Industry, Journal of Ambient Intelligence and Humanized Computing, 10(5), 2063-2090.

[https://doi.org/10.1007/s12652-018-0814-3]

-

Sarkar, B. (2012), An EOQ Model with Delay in Payments and Time Varying Deterioration Rate, Mathematical and Computer Modelling, 55(3-4), 367-377.

[https://doi.org/10.1016/j.mcm.2011.08.009]

-

Sarkar, B. (2013), A Production-Inventory Model with Probabilistic Deterioration in Two-Echelon Supply Chain Management, Applied Mathematical Modelling, 37(5), 3138-3151.

[https://doi.org/10.1016/j.apm.2012.07.026]

-

Sarkar, B. (2016), Supply Chain Coordination with Variable Backorder, Inspections, and Discount Policy for Fixed Lifetime Products, Mathematical Problems in Engineering, 2016.

[https://doi.org/10.1155/2016/6318737]

- Sarkar, B., and Saren, S. (2017), Ordering and Transfer Policy and Variable Deterioration for a Warehouse Model, Hacettepe Journal of Mathematics and Statistics, 46(5), 985-1014.

-

Sarkar, B., Omair, M., and Kim, N. (2020), A Cooperative Advertising Collaboration Policy in Supply Chain Management Under Uncertain Conditions, Applied Soft Computing, 88, 105948.

[https://doi.org/10.1016/j.asoc.2019.105948]

-

Saxena, N., Sarkar, B., and Singh, S. R. (2020), Selection of Remanufacturing/Production Cycles with an Alternative Market: A Perspective on Waste Management, Journal of Cleaner Production, 245, 118935.

[https://doi.org/10.1016/j.jclepro.2019.118935]

-

Taleizadeh, A. A., and Moshtagh, M. S. (2019), A Consignment Stock Scheme for Closed Loop Supply Chain with Imperfect Manufacturing Processes, Lost Sales, and Quality Dependent Return: Multi Levels Structure, International Journal of Production Economics, 217, 298-316.

[https://doi.org/10.1016/j.ijpe.2018.04.010]

-

Tayyab, M., Jemai, J., Lim, H., and Sarkar, B. (2020), A Sustainable Development Framework for a Cleaner Multi-item Multi-stage Textile Production System with a Process Improvement Initiative, Journal of Cleaner Production, 246, 119055.

[https://doi.org/10.1016/j.jclepro.2019.119055]

-

Tiwari, S., Ahmed, W., and Sarkar, B. (2019), Sustainable Ordering Policies for Non-instantaneous Deteriorating Items Under Carbon Emission and Multi-trade-credit-policies, Journal of Cleaner Production, 240, 118183.

[https://doi.org/10.1016/j.jclepro.2019.118183]

-

Ullah, M., and Sarkar, B. (2020), Recovery-channel Selection in a Hybrid Manufacturing-Remanufacturing Production Model with RFID and Product Quality, International Journal of Production Economics, 219, 360-374.

[https://doi.org/10.1016/j.ijpe.2019.07.017]

Appendix

<Appendix>

The first-order partial derivatives are as follows:

, , , , .

The values of J1, J2, J3, J4, and J5 can be calculated as follows:

Mitali Sarkar received the Ph. D. degree in industrial and management engineering from Hanyang University, South Korea, in 2017. She was a Postdoctoral Fellow with the Department of Industrial Engineering, Seoul National University, Yonsei University, and Hanyang University. From 2018 to 2019, she was an Adjunct Professor with Hanyang University. She is currently a Postdoctoral Researcher with Chung-Ang University.

Byung Do Chung is an Associate Professor in the Department of Industrial Engineering at Yonsei University. He received the B.S. and M.S. degrees in in Industrial and Systems Engineering from Yonsei University, and the Ph.D. degree in Industrial Engineering from the Pennsylvania State University. His research interests include supply chain management, smart factory, and mathematical optimization.

Jae Seok Choi received the B.S degree in industrial engineering from the Yonsei University. He is in master's degree at the Yonsei University. His research interests are logistics and optimization.